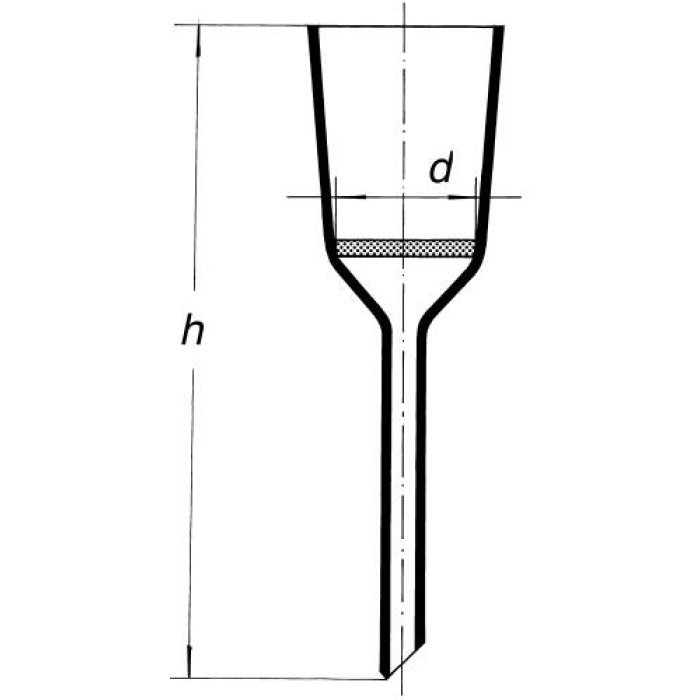

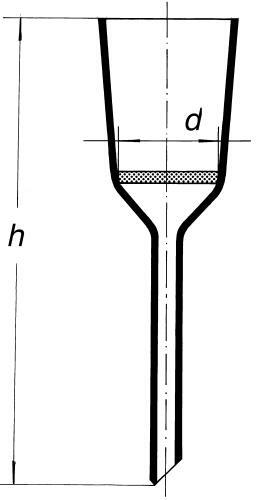

Nutch filter - Funnel, porosity S 3, 90 ml

By buying you get

11 Points

More than a purchase. You get service and expert advice. Ask which products and combinations are recommended for you.

Glass sintered filters are produced from exactly assorted glass detritus, which is acquired from chemical and heat resistant glass 3,3 type. The glass detritus is adjusted after assorting to the required shapes and sintered. The final product is defined according to the average size of the pores in mm and made in versions S 0 up to S 4 as mentioned further. Sintered discs can be heated up to 530°C. Heating and cooling need to be gentle. Before first use it is necessary to scour the new filter with the hot concentrated hydrochloric acid and later on by the cool distilled water to clear away any glass chips. Use adequate quantity and pressure of water. Filters need to be cleaned mechanically with water scouring or chemically with the reagent after every use. Except for mentioned items we can supply other products with sintered glass filters on request.

| Size of pores [µm] | Marking | New marking acc. to ISO 4793 | Water pressure [Pa] |

|---|---|---|---|

| 160 - 250 | S 0 | P250 | 1 200 - 1 900 |

| 100 - 160 | S 1 | P160 | 1 900 - 3 000 |

| 40 - 100 | S 2 | P100 | 3 000 - 7 300 |

| 16 - 40 | S 3 | P40 | 7 300 - 18 300 |

| 10 - 16 | S 4 | P16 | 18 300 - 75 200 |

- Volume [ml]

- 90

- d x h

- 90 x 245 mm

- Quantitative unit

- ks

Nutch filter - Funnel, porosity S 3, 90 ml